TECH

Brazilian consortium develops 3D printing of metal parts

Brazilian consortium develops 3D printing of metal partsAdditive Manufacturing

A consortium of Brazilian universities, industries and research institutions is working to advance the development of additive manufacturing combined with machining processes - in simpler terms, 3D printing of metal parts."In the near future, mechanical, automotive and aeronautical parts and components, as well as human prostheses, can only be built using this new technology. If in Brazil we do not learn at least to use this process, we will be far behind." Reginaldo Teixeira Coelho, professor at the USP School of Engineering in São Carlos (SP).This innovative manufacturing technology, which aims to at least partially replace traditional casting, forging and machining processes, has attracted the interest of different research groups around the world.In Brazil, the main research institutions working in the field of additive manufacturing met through a project supported by FAPESP (Foundation for Research Support of the State of São Paulo) to align efforts and, knowledge and application of this new technique.

3D printing for metals

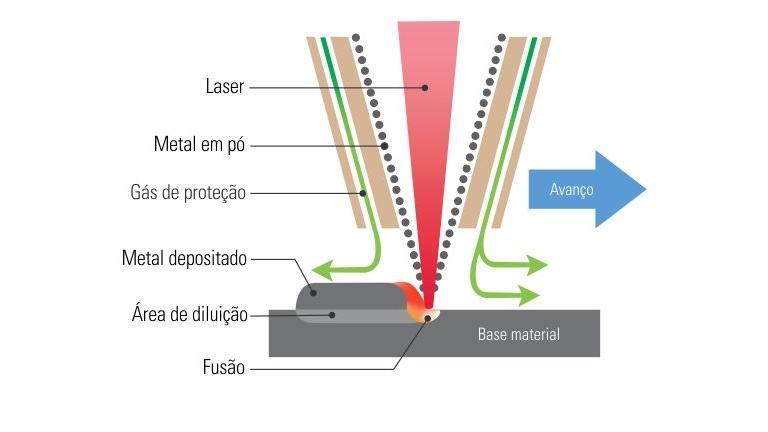

The technology studied by the team is based on two metal 3D printing processes, called powder bed fusion (FDF) and direct energy deposition (DED).The first process is to fuse sequential layers of a metal bed with a laser beam while the second involves the concomitant use of the laser beam and metal powder injected into a pool of molten metal on the surface of a part.As the metal powder is melted, the material layers and cools and solidifies to form a metal part, based on a digital model. "This process is well developed for polymers, but for metals it still poses a very big challenge," Reginaldo said.One of the challenges to make the technique feasible, according to the researcher, is to adapt the laser energy necessary for the fusion of the materials. While the polymers melt between 100 ° C and 250 ° C, the melting temperature of most metals is above 1,000 degrees, which requires very high energy. "The challenge is to achieve optimum energy concentration that allows the equipment to reach that metal melting temperature," he said.Another challenge is the surface finish of the metal parts obtained by additive manufacture, since they may not meet some high performance applications. For this, it is necessary to combine it with processes such as machining.FAPESP/IPT/School of Engineering in São Carlos (SP)

No comments:

Post a Comment