TECH

3D Electronics: How to build a chip on top of another

3D electronics

Silicon integrated circuits, like computer processors, are approaching the maximum viable transistor density, so any new ideas are welcome.

Because these current chips are typically two-dimensional, with transistors manufactured on a flat silicon plate, three-dimensional components such as 3D transistors and even 4D transistors have long been working.

This has helped, but the manufacturing techniques are complicated and expensive, and do not apply to all electronic components.

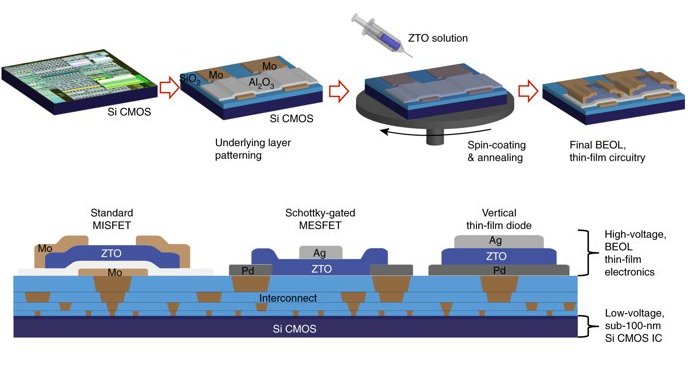

To circumvent these drawbacks, Youngbae Son and colleagues at the University of Michigan, USA, created a much simpler technology: Using the same current technology to stack a second layer of transistors directly on top of a ready-made integrated circuit, creating non-3D components, but a "3D electronics".

They achieved this by using a different type of semiconductor, known as amorphous metal oxide. To apply this semiconductor layer to the silicon chip without damaging it, they coated the chip with a solution containing zinc and tin and rotated it to create a uniform layer.

After this layer was dried in an oven, the process was repeated to form a zinc-tin oxide layer about 75 nanometers thick. During final heating, the metals bound to oxygen in the air, creating a layer of zinc-tin oxide that was used to create the transistors by traditional lithography.

Monolithic Integration

While not applicable in all cases, this design eliminates the need for a second chip to convert between high- and low-voltage signals, which currently sits between low-voltage processing chips and user interfaces, High voltage

Higher voltages could damage smaller and smaller transistors, which means that next-generation processing chips are no longer compatible with high-voltage user interface components, which need to operate at higher voltages to avoid effects such as signals. false ring tones or very low brightness settings on monitors.

Since the second layer of transistors can withstand higher voltages, they essentially give each silicon transistor its own interpreter to talk to the outside world. This avoids the current cost of using high-end processors with an extra chip to convert signals between the processor and interface devices - or using a lower-level processor that runs at a higher voltage.

According to the team, their prototypes pave the way for silicon integrated circuits that go beyond Moore's Law, bringing the analog and digital advantages of oxide electronics to next-generation silicon chips.

Authors: Youngbae Son, Brad Frost, Yunkai Zhao , Rebecca L. Peterson

No comments:

Post a Comment