TECH

Engines for the airplanes of the future

The European Union's vision for aviation in the European Union focuses on reducing aircraft energy consumption and CO2 emissions per passenger-kilometer by 75% by 2050.However, this goal would not be feasible if the aviation industry relied solely on the incremental improvements of the state-of-the-art technologies presented to each aircraft launch by the industry.Part of the reduction needs to be achieved through radical new technologies. This is the goal of the Ultimate project, funded by the European Union itself."To achieve the 75% reduction target, it is estimated that the last 18% will have to come from the revolutionary technology developed in Ultimate," said Tomas Grönstedt, a professor at Chalmers University of Technology in Sweden and project coordinator.The team, which brings together several other universities, sought to address the three main sources of energy loss in today's aircraft engines: the irreversibility of the combustor, the core exhaust heat and the kinetic energy of the exhaust. Together, they account for more than 80 percent of the total energy losses of today's airplane engines.

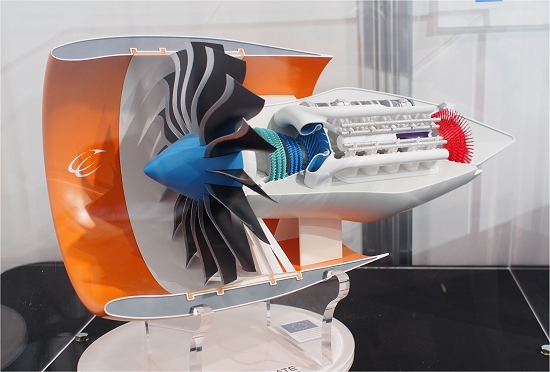

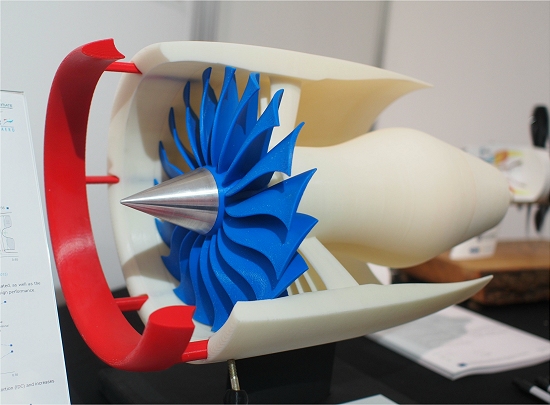

The crossing of the solutions presented resulted in eight new aeronautical engine concepts.Two designs revolve around the concept of pre-cooled cores and pulsed detonation combustion. Pre-cooling of the core stream prior to blasting improves volumetric efficiency, allows higher rates of combustion pressure, reduces the risk of pre-ignition, and reduces engine cooling requirements. Project partners have proposed a project for flights within Europe and a variant, using turbofans with gears, for long-haul flights.Three concepts focused on more advanced engine versions. The first, an open rotor with an oscillating disk cycle, tackles the inefficiencies of the components of the open rotor scheme by introducing top cycles.

The other two concepts include a turbocharger with closed loop bottom cycle and a turbocharger that combines an open circuit air bottom cycle with a swing disc, intercooler and secondary combustion cycle.

The ultrafine adaptive inlet concept proposed by the design, in turn, offers a potential solution to improve the operation of ultra high bypass turbocharged engines equipped with thin and short nacelles.

Another novelty is a concept of a secondary fluid recuperator, in which two heat exchangers were installed inside the engine core. Finally, the compound cycle engine combines conventional gas turbines with piston engine solutions.

"We are now on track to mature these technologies to technology level ready [for adoption]," Grönstedt said.

Source:Ultimate Project

No comments:

Post a Comment