TECH

Carbon Fiber Stores Energy in Cars Bodywork

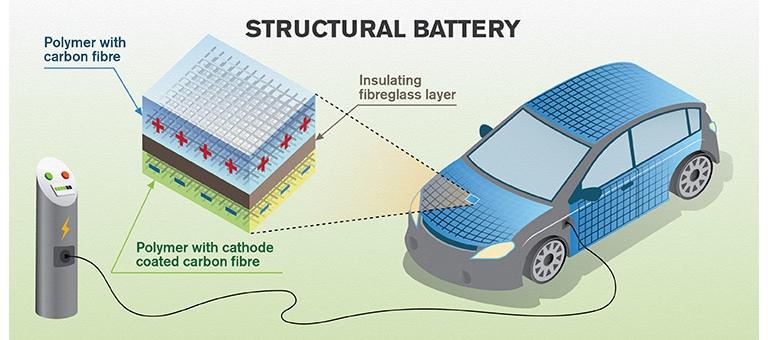

Structural battery

A few years ago, engineers have been trying to turn car bodywork into "laterias", structural and safety parts that are both capable of storing energy.A team from Sweden has now discovered how to make carbon fibers work as lithium battery electrodes, storing energy directly.The use of this type of multifunctional material can contribute to a significant weight reduction and increase in the autonomy not only of hybrid and electric cars, but also of electric aircraft - passenger planes will need to be much lighter than current ones to be powered by electricity ."The body of a car would then simply not be a load-bearing element, but would also function as a battery. It would also be possible to use carbon fiber for other purposes, such as kinetic energy harvesting, for sensors, or as If all these functions were part of the structure of a car or an aircraft, it could reduce weight by up to 50 percent, "said Professor Leif Asp of Chalmers University of Technology.

Carbon fiber battery

Professor Asp led a multidisciplinary group that demonstrated that the microstructure of carbon fibers affects their electrochemical properties, ie their ability to operate as an electrode on a lithium-ion battery - the electrodes of lithium batteries are typically made of carbon, although not in the form of fibers."Now we know how multifunctional carbon fibers must be fabricated to achieve a high energy storage capacity, in addition to ensuring sufficient stiffness," said Asp. "A slight reduction in stiffness is not a problem for many applications such as cars.The market is currently dominated by expensive carbon fiber composites whose rigidity is adapted for use on airplanes.There is therefore some potential for fiber manufacturers increase their use. "In fact, the types of carbon fiber with good electrochemical properties to function as batteries have a slightly higher stiffness than steel, while the types with the worst electrochemical properties are only twice as rigid as steel.Thus, for the aviation industry, it may be necessary to slightly increase the thickness of the carbon fiber composites to compensate for the reduction of the stiffness of the parts when it is transformed into structural batteries, but this would bring the additional benefit of increasing its storage capacity power."In addition, the lower energy density of the structural batteries would make them safer than standard batteries, especially since they would also contain no volatile substances," said the researcher, adding that the team is already in collaboration with the automotive and aviation sectors to start technology testing.

Source:Graphitic microstructure and performance of carbon fiber Li-ion structural battery electrodes

Giulia Fredi, Steffen Jeschke, Athmane Boulaoued, Joachim Wallenstein, Masoud Rashidi, Fang Liu, Ross Harnden, Dan Zenkert, Johan Hagberg, Göran Lindbergh, Patrik Johansson, Lorenzo Stievano, Leif E. Asp Multifunctional

No comments:

Post a Comment